Various ideas

Here are a few ideas that could find their ways into models at some point...

Here is a simple locking diferential: the first picture shows how it can be integrated with a motor, the second view shows the unlocked position and third view shows the locked position.

Here is an idea for a pneumatic steering linkage that has three positions: left, right and strait. Whithout this linkage, it is very hard to go in a strait line! On this prototype, the blue pieces are one half of the truck and the yellow pieces are the other half. The first picture shows the controller.

Here is a solar powered railcar. It uses one Technic motor powered by two Lego solar panels. The axles are from Bachman, with their wheels re-gauged from 45mm to fit the Lego track. This model does not run well indoors, probably because the light bulbs I use have the wrong light spectrum for the solar panels... I will probably re-gauge the wheels to 45mm so I can run it on my garden railway.

One thing that I've been trying to build over the years is a front wheel drive car with steering. I've built several big models with some mixed results. Then I saw the newest bevel gears that came with kit 8448 and I realized that I could build a very small front wheel drive car. It is not a very realistic mechanism, but it works!

Here is a prototype of a solid axle suspension with coil springs and Watt linkage. The blue parts move with the axle, the brown parts are part of the vehicle's chassis and the yellow parts are the Watt linkage. This idea is used in my 4404 upgrade.

Here is a short movie showing the Watt linkage in motion (4MB file, 10~15 minutes download with a 56K modem).

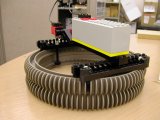

When I first saw the "Hail Fire Droid" set, with its 8" diameter wheels I immediately thought about using them as part of a roller bearing.

At first I was disapointed: no hard (i.e. without tire) wheel would fit just right between the two rings. Then I realized that if I "raised" the wheels a little bit it would work! It turns out that an exact number of 3 stud long lift arms fit inside the ring's groove. This extra half stud of thickness does the trick and the result is a very strong bearing: I was able to stand up on it and spin around...

I intend to incorporate this bearing in a big crane. Obviously the motor used for rotating it will be a bit more powerful than the one shown below...